Heli-Coil® Primer-Free® Coated Inserts

Eliminate the need for costly primers and epoxies.

Primer-Free® inserts are designed for use in applications where galvanic corrosion between dissimilar metals is a concern. The proprietary Primer-Free® coating not only protects the base material and provides excellent lubricity, but more importantly, eliminates the need for liquid chromate primers. With Primer-Free® coated inserts, the inserts are always evenly coated, providing more accurate bolt torques. When utilizing Primer-Free® inserts, installation time is reduced significantly and total in-place cost is decreased dramatically.

- Contains no Hexavalent chromium

- Eliminates need for chromate primers

- Provides added lubricity for easier installation

- No additional hole preparation necessary

- Ideal for aluminum & magnesium applications

- Meets Aerospace Standards

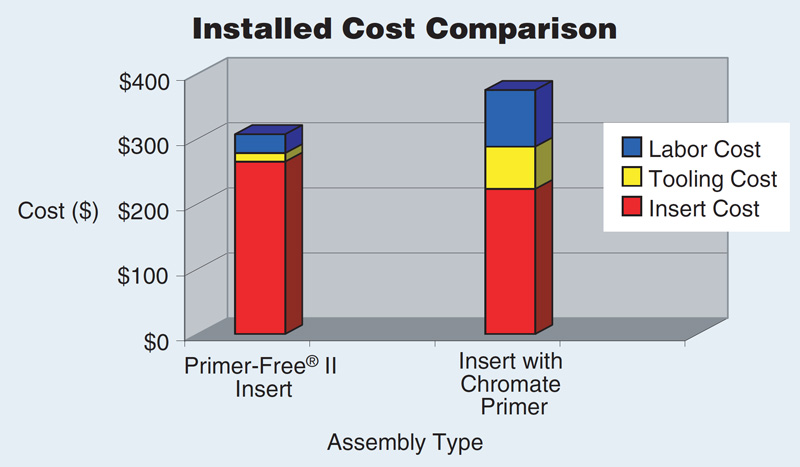

The chart above illustrates the significant difference in installed cost when comparing Primer-Free® inserts with inserts coated with liquid chromate primer. Significant savings - in excess of 20% - can be achieved when utilizing Primer-Free® inserts. These savings are largely due to the elimination of the application of the liquid chromate primer, which is a labor-intensive process and often results in inconsistent coverage of the threads.

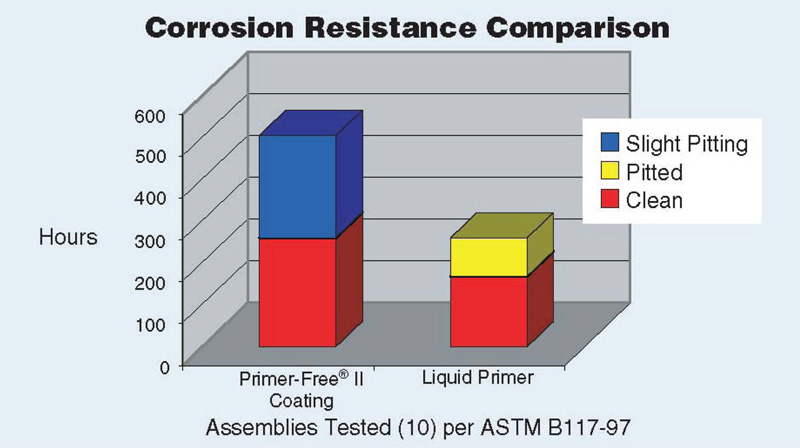

Primer-Free® inserts have undergone extensive salt fog testing per ASTM B-117. After exposure, the samples were sectioned to expose the threaded insert for examination. When protecting against galvanic corrosion, Primer-Free® inserts did consistently meet or exceed the performance of insert assemblies containing liquid chromate primer.